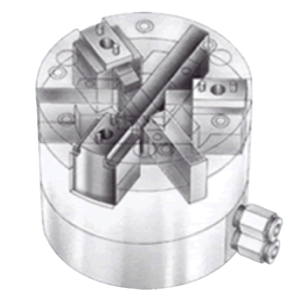

Ultra-precision

The wedge type mechanism ensures repetitional chucking accuracy as high as 2um. No center alignment is required for each chucking.

Compact design

The compact chuck with built-in air-actuated mechanism are available in outside diameters of 2, 3 and 4 inches. Even a multiple number of air chucks can be installed in a limited space, making them perfect for chucking work in various types of loading and unloading devices.

Soft-touch chucking performance

Naka air chucks can operate at a pneumatic pressure between 0.6 and 6 kgf/cm2. The chucking force is adjustable freely by using a pressure regulator so that even a warkpiece of thin wall thickness or a workpiece susceptible to deformation can be chucked.

Accurate chucking

Fit in place, each of the jaws can move precisely parallel, allowing positive gripping of work even with 1mm or less chucking allowances.

Both outside and inside chucking

The same jaws of each Naka air chucks can be used for both outside and inside chucking.

Wide range of applications

Naka air chuck series comes in variety of sizes(O.D. of 2, 3 and 4 inches), types(stationary and rotary types), jaws(2, 3 and 4 jaws), jaw strokes(2, 5 and 10mm) and oil supply systems(coolant and oil mist). So they can securely grip even workpieces of complicated shapes, making them adaptable to a wide range of applications including turning, drilling, milling, grinding, assembling and inspection etc.

Warning: Trying to access array offset on value of type bool in /home/nlcsgp/public_html/wp-content/themes/miunlc/single-product.php on line 112

Warning: Trying to access array offset on value of type bool in /home/nlcsgp/public_html/wp-content/themes/miunlc/single-product.php on line 112

*Call and consult us for further information or selection of the most effective unit that meets your requirements such as liquid types and viscosities.

SIMILAR PRODUCTS

Presses

NAKA Press can be used in many different jobs. Its simple, sturdy construction with ease of operation ensures improved productivity.

Precision Machining

Incorporating the latest technology use of CNC machines and Rotary Transfer Machine. For precise and quality work.

Dynamark – High Air Energy Hammer

Dynamark performs scores of efficiency than equivalent pneumatic cylinder for the short stroke working. Ex. Riveting , Punching, Deburring etc.