Specialist in

Liquid Control

Technology

With global experience and market leaders in manufacturing and precision engineering, NLC specialises in liquid control technology.

Discover our ProductsNAKA LIQUID DISPENSERS

Reliable, efficient and productive

Nu I/II

The Nu I/II - our flagship model for micro volume discharge is now available in a lineup of NLC-original volumetric (plunger pump) dispensers.

Kappa 5

The "KAPPA Series" is 2-component dispensers for small quantity that have obtained an implicit trust in various industrial fields.

Kappa 5 Dual Servo

The Kappa 5 DUAL SERVO, a variation of the Kappa 5, features dual servo drive and offers improved operability and cost-performance without altering its compactness.

TWINFLOW VR-50/100

A high-precision volumetric metering system that dispenses fixed volumes free from the effects of changes in liquid viscosity.

HR-50

This 2-component dispenser operates two posi-load metering pumps using a double-rod air cylinder.

TRISTAN 50/100

This volumetric metering type posi-load pump contributes to high-precision metering and dispensing since it is not affected by changes in material viscosity.

MP-502

These 2-component mixing dispensers incorporate our original plunger pumps in the metering mechanism, featuring simple design and offering functional enhancement.

eco-DUO 450

The eco-DUO450 is a 2-component constant-flow volumetric discharging device, newly developed by ViscoTec.

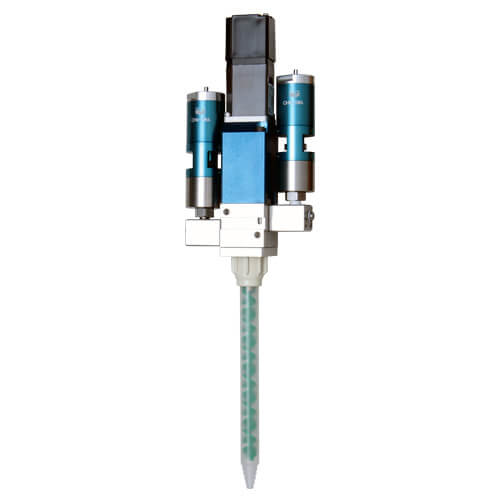

Robot dispenser

2-component resins, accurately discharged from the volumetric metering plunger pump and mixed in the static mixer attached to the robot, are applied through the nozzle mounted after the static mixer on the robot.

Vacuum encapsulating systems

For high quality manufacturing, NLC provides custom-made Vacuum encapsulation systems to your requirement.

Posi-load metering pumps 50/100

The mechanism of this dispenser is simple with a metering section below the tank.

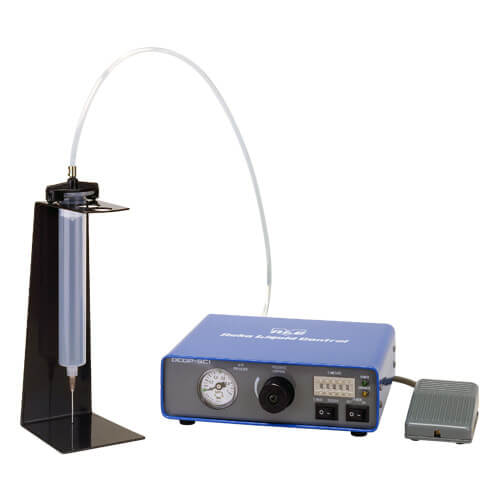

DCOP – SC1

This new general-purpose dispenser offers excellent value. Offering all the essential functions of a barrel dispenser in a compact unit, this general-purpose single-component dispenser represents very good value.

DCOP – D

DCOP-D is a dispenser incorporating a dosing valve that opens and closes by air pressure. Liquid dripping can be prevented for accurate operation.

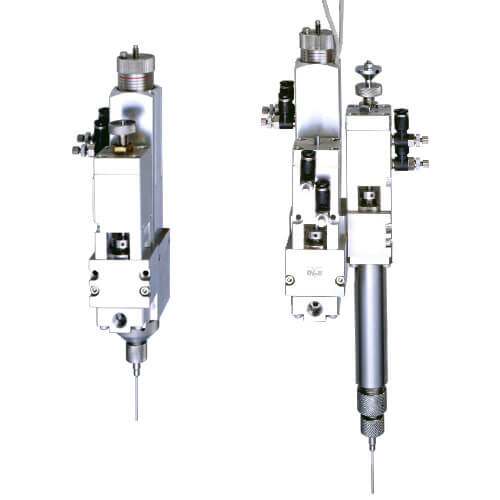

Micro plunger pump

This plunger pump, incorporating the volumetric metering system, is capable of discharging small volumes with high precision.

Robot dispenser

Resin accurately metered with the volumetric metering plunger pump is applied through a nozzle attached to the robot.

Eco PEN 300/450/600

The eco-PEN 300/450/600, developed by ViscoTec, is a new and innovative constant-volume volumetric dispenser, suitable for micro-volume dispensing of low to medium viscosity liquids in diverse applications.

Liquid discharging valves V series

Designed to be compact and lightweight, the V series is best suited for mounting in close contact with a robot.

Static mixer

Improves mixing work and prevents environmental pollution with chemicals of short pot life or unwashable mixes.

Replacing-type Mixer

New! Eco-friendly mixer that replaces chemicals without requiring washes or solvents

Rotary static mixer unit

This rotary static mixer unit is an innovate type of mixer that combines the advantages of both dynamic and static mixers.

Type S nozzle

Provided with a highly durable stainless steel needle. Accepts 12 needle sizes (25G to 11G) to accommodate dispensing of even very small amounts of low-viscosity liquids.

Type L nozzle

Provided with a highly durable stainless steel needle. Accepts 6 needle sizes (14G to 7G) to accommodate dispensing of even large amounts of high-viscosity liquids.

Syringe nozzle (Full length 48mm)

Low-cost nozzle with stainless-steel needle bonded to polypropylene boss with epoxy resin. Customized for syringe applications.

Syringe nozzle (Full length 30mm)

Syringe nozzle featuring four-winged and doublethreaded boss to ensure a tight connection with the syringe.

Flexible nozzle

Resin nozzle ideal for anaerobic liquids. The resin needle prevents anaerobic liquids from curing within and enables dispensing in narrow spaces without damaging the product.

Taper nozzle

The tapered tube inside the nozzle ensures smooth liquid flow. Ideal for dispensing of medium- and highviscosity liquids.

Precision taper nozzle

The precisely machined one-piece molded nozzle ensures highly accurate dispensing of very small amounts.

Poly nozzle 1/4″

One-piece molded polyethylene nozzle with taperthreaded connector for 1/4 inch pipe. The tapered tube inside the nozzle reduces resistance and allows for high liquid flow.

Resin nozzle for DV

All-resin nozzles: PTFE nozzle for dispensing anaerobic resins, and POM-BC nozzle for dispensing UV curable resins.

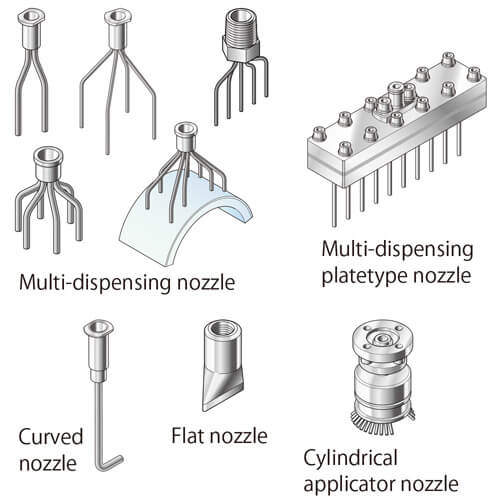

Special nozzle

We offer a wide variety of needle sizes and boss types. We can also provide custom-designed nozzles in any shape to meet your requirements.

PT type (Standard Tanks)

This tank is suitable for liquids of low-to-medium viscosity. No tank stand is required. The liquid flows upward and out through the pipe attached to the top plate of the tank when the tank is pressurized with air.

DFAL type (Tanks with Level Gauge)

To indicate the liquid level, the level-detecting rod (linked to a float) provided at the center of the tank rises and falls as the liquid level changes.

EM type (Tanks with Electric Mixer / Bottom Pressure-feed System)

This tank is equipped with an electric mixer.

KPT type (Cartridge Tank)

Two types of cartridge tank are available: one accommodates a 330ml commercial cartridge (KPT-1); the other uses a liquid-filled PP cartridge.

The Nu I/II – our flagship model for micro volume discharge is now available in a lineup of NLC-original volumetric (plunger pump) dispensers. The new functions and mechanics for ensuring high-accuracy discharging meet high-level requirements.

- Modularised unit for working with various types of resin.

- Unique pump structure for easily bleeding air even with high-viscosity liquids

- Constant inner pressure for stable discharging*

*Nu II only - The 7″ wide colour screen displays various information at the same time.

Compact and lightweight aluminum casing makes the panel readily mobile.

| Discharge range | 0.036 - 5ml *1 |

| Mixing ratio | 100 :100 - 100 :50 *2 |

| Viscosity range | 1 - 300,000mPa・s |

| Material tank | 330-ml-cartrige tank or 2.5-kg-container tank |

| Mixer | Static mixer |

| Metering system | Volumetric metering(Plunger type) |

| Drive system | Servo motor drive |

| Air supply | 0.4MPa(Dry air) |

| Power consumption | AC200V・1.2kW |

*Call and consult us for further information or selection of the most effective unit that meets your requirements such as liquid types and viscosities.

The “KAPPA Series” is 2-component dispensers for small quantity that have obtained an implicit trust in various industrial fields. As its latest model, we provide the “KAPPA 5”. The introduction of a touch panel further improves its operability. The simple body design ensures improved work efficiency and a clean, comfortable working environment.

- This volumetric metering type posi-load pump contributes to high-precision metering and dispensing since it is not affected by changes in material viscosity.

- Compared with our conventional models, the “KAPPA 5” has various timers as standard equipment to enhance its functions.

- Compact and easy-to-operate model that can easily be set up in a small installation space.

- A miniature high-speed brushless motor with quiet operation sound is used for the mixer, providing more comfortable working environment.

| Discharge range* | 0.03 - 2.0 ml/shot (Varies depending on pump combination.) |

| Mixing ratio* | 100:100 - 100:5 |

| Viscosity range* | 1 - 300,000 mPa・s (Higher viscosity material may be used by heating.) |

| Material tanks | 1L for resin, 1L for hardener (Square SUS tanks) |

| Flushing tank | 10L force-feed tank (SUS) |

| Mixer | Dynamic or static mixer |

| Metering system | Volumetric metering (Posi-load type) |

| Drive system | Air cylinder drive |

| Control system | Sequence control (PLC) |

| Air requirement | 0.4 MPa minimum (Dry air) |

| Power consumption | AC100V・500W |

| Main body dimensions | 535 (H) x 350 (W) x 615 (D) mm |

*Call and consult us for further information or selection of the most effective unit that meets your requirements such as liquid types and viscosities.

High-precision volumetric metering system ensures that products continue improving

The volumetric metering system contributes to high-precision metering since it is not greatly affected by changes in liquid viscosity.

The discharging liquid must be completely degassed before vacuum potting in customers products. Our original design is used in every section of the Vacuum encapsulating systems to degas the resins in tanks and ensure that the liquid path is sealed.

*Call and consult us for further information or selection of the most effective unit that meets your requirements such as liquid types and viscosities.

NAKA PRODUCTS

Presses

Learn More

Precision Machining

Learn More

Dynamark – High Air Energy Hammer

Learn More

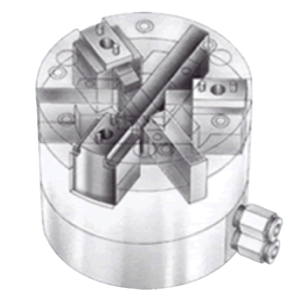

Air Chucks

Learn MoreContact

NLC Singapore Pte. Ltd.

- 50 Bukit Batok St.23,

#04-11 Midview Building,

Singapore 659578

Tel: +65-6268-5911

Fax: +65-6268-2170

Email: info@nakaps.com.sg

Naka Liquid Control Co. Ltd.

- 18-1, 2 Chome Dainichi-cho,

Moriguchi-shi, Osaka

570-0003, Japan

NLC (Thailand) Co., Ltd.

- 49/162 Moo 7, Nongsue-Bangkan Road,

Tambol Khlongsong,

Amphur Khlongluang Pathumthani

12120, Thailand

Weihai Naka Liquid Control Co. Ltd.

- 5 Lianqiao Japanese Industrial

Park, 198 Tianjing Road,

High-tech Industry Development Zone Weihai,

Shandong, China 264209

Enquiry

Send us your inquiry and we will help you as best as we can. We typically respond within 6 hours!

PRODUCTS

Copyright © NLC Singapore Pte. Ltd. All Rights Reserved.